Our Products

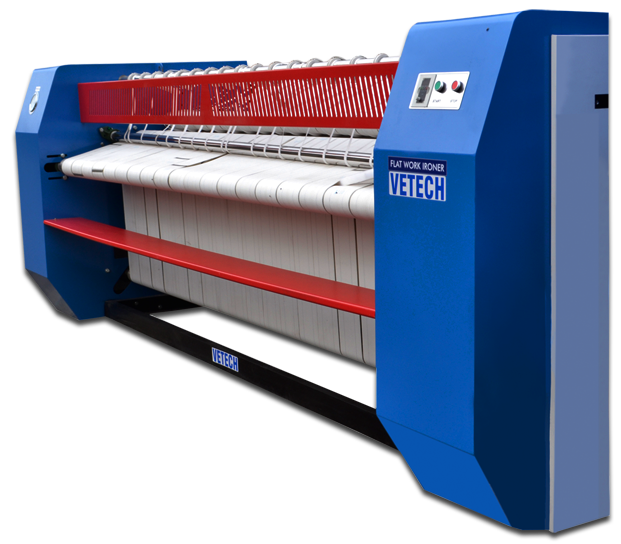

Flat Work Ironer

a) with heated chest & rear return

b) with heated chest & return feed type

c) with heated roller & rear return type

Roller having large diameter with moving ironing chest, large diameter ensuring a long contact surface, flexibility for addition of another roll, powerful suction for fast drying finger guard for operator safety, flexibility for changing of roller speed through VFD.

Optional :- Imported spring padding & frequency control drive for required roller speed

S.S. Roller perfectly machined and having large diameter with perfect 180 Plus contact with roller. finger guard for operator safety

Stainless steel raw material of roller constructure-300 degree effective angle of sheet improve of the heating area and speed. equipped with frequency speed control, one competed chain transmition design available in steam or electric or gas heated.

Roller Size available :- 800x3000mm,800x1800mm,600x1600mm

ironing speed 6 mtr. per mint, steam pressure 0.6-0.6 mpa or electric power 32.4 kw, motor power -0.75 kw

Technical Specification

|

Roller Size Dia X Length

|

Drive Moter

Suction Motor |

Air Connection

Consumption |

Heating

|

Overall Dimensions WXDXH

|

||

|

Steam

Connection Consumption |

ThermicFluid

Connection Consumption |

Electric

Heated |

||||

|

830 x 3300

Sigle Roller |

5.6 KW

|

0.5″ BSP

100LTS/MIN |

1″BSP

150 KG/HR. |

0.5″ BSP

60000 KCAL/HR. |

36 KW.

|

4800 x 2200 x 1800

|

|

0.75 KW

|

||||||

|

830 x 3300

Double Roller |

7.5 KW

|

0.75″ BSP

200LTS/MIN |

1″BSP

300 KG/HR. |

0.75″ BSP

120000 KCAL/HR. |

………………

|

4800 x 3300 x 1800

|

|

0.75 KW (2 NOS.)

|

||||||

|

380 x 3000

Return Feed Type |

0.75 KW

|

0.5″ BSP

25LTS/MIN |

0.5″BSP

40 KG/HR. |

0.75″ BSP

16000 KCAL/HR. |

18 KW.

|

3700 x 1050 x 1370

|

|

0.37 KW

|

||||||

|

800 x 3300

Roller Heated |

5.6 KW

|

………………

|

150 KG/HR.

|

………………

|

36 KW.

|

4300 x 2000 x 1600

|

Automatic Folder

Folder Machine.

1. PLC control system, intelligent touch screen, dynamic display folding condition can realize man-machine dialog and reserve 5 sets of folding program.

2. Two horizontal with three vertical function, first 3 step by pneumatic fold, later two step by mechanical folding knife can realize maximum 5 with 32 layer folding.

3. Two sets of independent drive motor control by inverter, it is infinitely function within 50m/min folding speed per hour can realize fold article 1000 sheets per hour.

4. High quality anti-static eliminate stick, all the guide roller with special destaticization to reduce static from linen effectively. cloth enhance the rate of folding, increase the reliability and stability of the machine.

5. All light, electricity, bearings, variable frequency components all imported from Japan and European imported supporting, increase the stability and durability of machine.